End-to-End Electronic Production Service

Elektroent is with you at every stage of your IoT electronic device development journey. Starting from prototype software with its expert staff, you can have PCB circuit design, component supply, typesetting and boxing services from a single source.

About UsElektroent Domestic

Electronic Hardware Production Base

-

Our target

At a time when the importance of domestic production is increasing and the use of technology is becoming widespread, our goal is to facilitate the product development processes of our customers by producing quality electronic hardware that is unit independent.

-

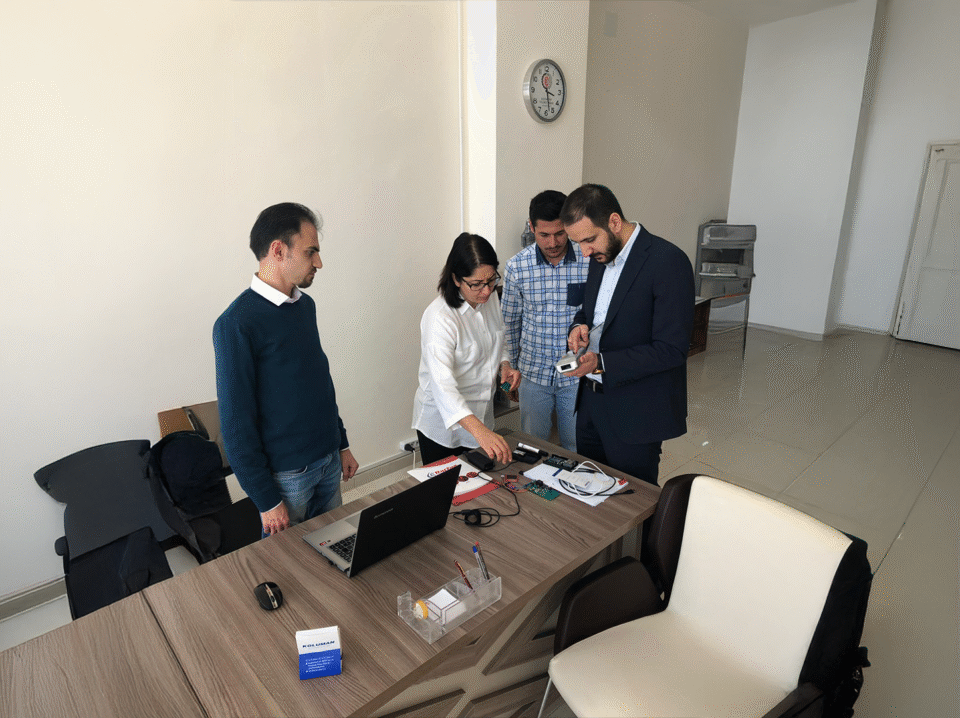

R&D

We are working with all our strength to announce domestic technologies to the world with our KOSGEB and TÜBİTAK supported projects that we carry out within Teknopark.

Our Solutions

Software Development Services for Embedded Solutions

- Application Development

- Integration Solutions

- Customized Software Solutions

- Safety and Performance Oriented Approach

PCB Design

- Printed Circuit Board Design Services

- Professional Design Process with Our Expert Staff

- Collaboration with the World's Largest PCB Suppliers

Test & Assembly

- Product Testing and Quality Control Processes

- Plastic - Metal Box Assembly

- In-Box Cable Grouping and Assembly

- Mebran - Label Assembly

SMD & THT Typesetting

- Technical Specifications for SMD and THT Assembly Processes

- Fully Automatic SMD & THT Assembly and Soldering

- Furnace and Heat Treatment: Precise Temperature Control

Component and PCB Supply

- Material Selection and Supply Management for Your Projects

- Quality Component Supply

- Professional PCB Supply

- Technology and Reliability

Full Professional Support in Electronic Typesetting

Electronic Production

With our state-of-the-art typesetting line facility, we can meet your high or low volume production needs at every stage from electronic card design to production. In this context, you can manage all typesetting processes from a single source in both small-scale projects and large-volume productions, and avoid surprises in R&D processes.

Plant and Equipment

In order to provide you with full professional support, we have JUKI brand SMD & THT typesetting machine with a capacity of 20.000 components/hour,

We have 12 zone SMD solder dryer oven, Automatic Optical Inspection Machine, Full automatic PCB screen printing, CNC Machine and various Testing Equipment.

The right solution partner for your projects

We collected the most frequently asked questions about all processes from PCB production to embedded software.

How many PCBs can I have produced? Is there a minimum order quantity?

From prototype to mass production From 1 piece starting production. With panel optimization, unit cost decreases as the quantity increases; there is no minimum order requirement.

Do you only manufacture PCBs or do you also provide assembly services?

We offer both services. Besides PCB production SMT/THT assemblyfunctional testing and quality assurance processes.

How does your embedded software development process work?

Analysis → architecture → hardware/OS selection → driver/library → testing & validation → maintenance. We move forward with agile sprints and close requirement risks early.

What do your testing and quality assurance processes include?

AOI/X-ray, functional jigs, environmental stress (heat-humidity), electrical safety and traceability reports. We complete with end-user acceptance tests.

How does your pricing and quotation process work?

With Gerber/BOM/PCBA documents 24-48 hoursa preliminary offer. We offer optional costing for alternative parts/stock risks.

BlogOur Articles

How to make SMD Led Stringing?

What is an Electronic Card?

TechnologyNews

Visit from the Chamber of Electrical Engineers

Our Quality is Certified with CE Certificates

Turnkey Project Development

-

-

Software and Prototype Development

New developments in today's technology have increased the demand for low energy consumption, high performance and cost-effective IoT hardware. In IoT hardware production, we offer the experience of our engineers over the years to the service of our valued customers

-

Production and Packaging

We use the latest production technologies and professional equipment to ensure high quality standards at every stage of your projects. We carefully process your products on our production line and meticulously manage all processes until packaging and delivery.

Our Portfolio

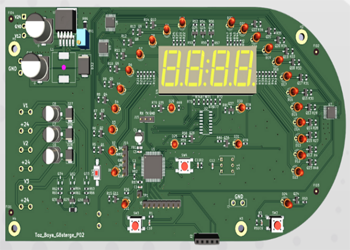

Access Control Panel Project

Security and access control are of critical importance for industrial companies. In this context, automated access control systems are becoming increasingly important in industry.

Smart Taxi Head Lamp with Status Notification

Smart Taxi Head Lamp with Status Notification (Taksimatik) developed as a result of the joint work of ElektroEnt and Istanbul Metropolitan Municipality

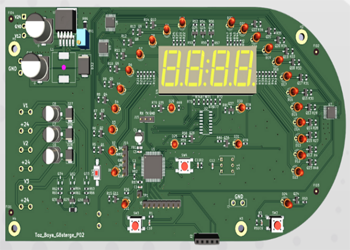

Powder Coating Control Card

One of the indispensable products of today's industrial companies is paints. In this context, paint machine production is of great importance and the most critical element that provides differentiation in this field is the control card.

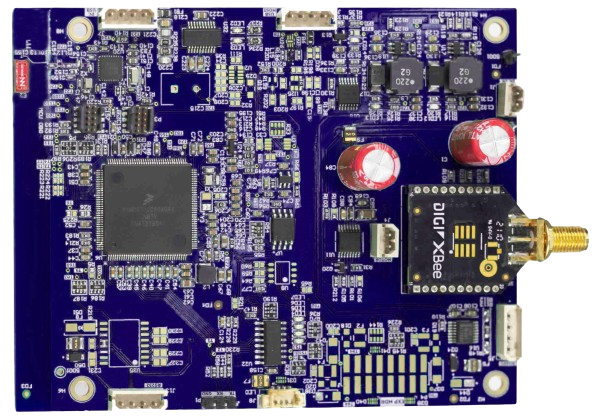

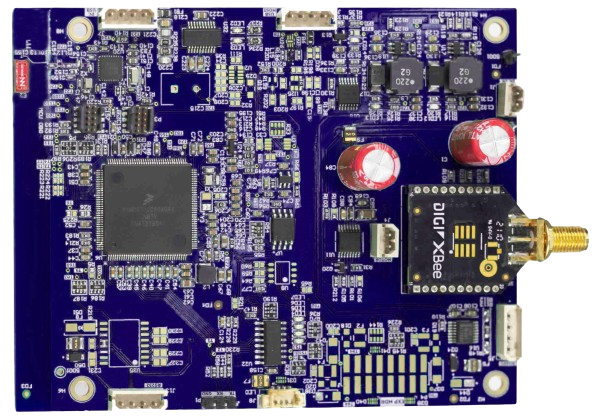

Car Charging Station GPRS Control Data Card

With the proliferation of electric vehicles, the importance of vehicle charging stations is rapidly increasing.

Access Control Panel Project

Security and access control is critical for industrial companies.

Smart Taxi Head Lamp with Status Notification

Smart Taxi Head Lamp (Taksimatik) with Status Notification developed as a result of the joint work of ElektroEnt and Istanbul Metropolitan Municipality.

Powder Coating Control Card

One of the indispensable products of today's industrial companies is paints. In this context, paint machine production is of great importance and the most critical element that provides differentiation in this field is the control card.

Car Charging Station GPRS Control Data Card

With the proliferation of electric vehicles, the importance of vehicle charging stations is rapidly increasing.

Our References