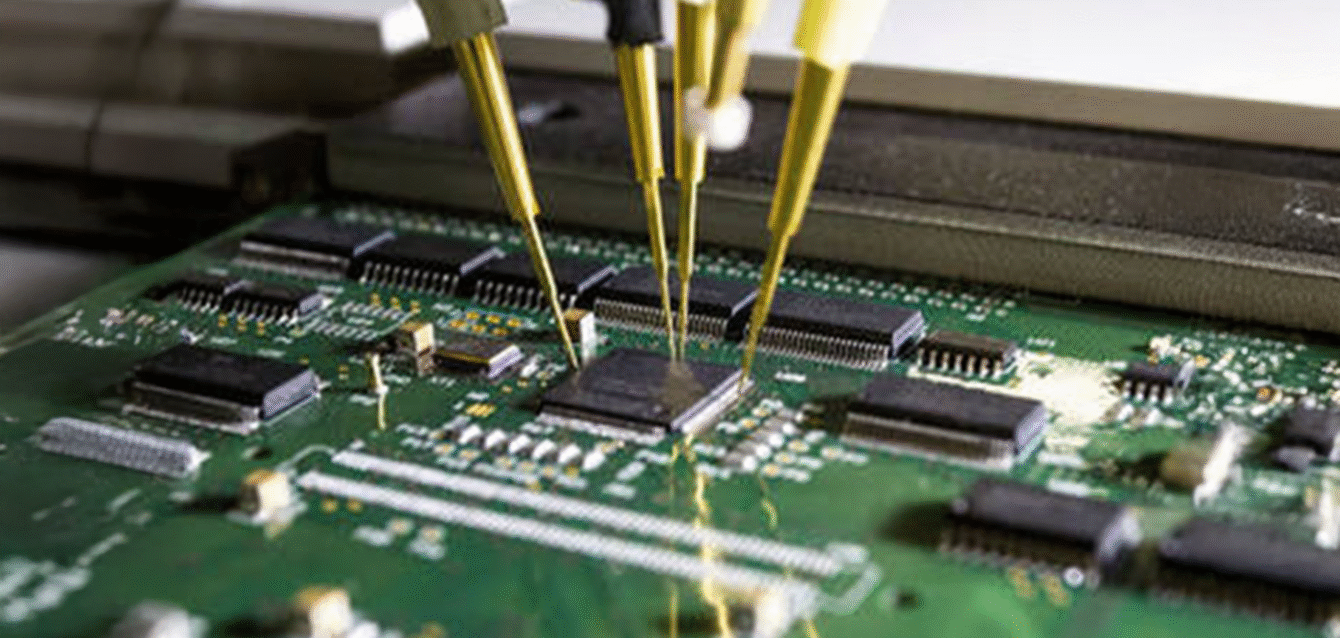

Before the actual circuit board assembly (PCBA) process begins, a number of preparatory steps need to take place, one of which is the DFM inspection, or production inspection for short. This inspection helps to evaluate the functionality of the PCB design. Companies specializing in PCB assembly often request the PCB design file, other design notes and special requirements. They audit the PCB file for any issues that could affect the PCB's functionality or manufacturing capability, detecting if there are any missing, redundant or potential problems. Without this inspection, any of these issues can seriously and negatively impact the final functionality of the project. In electronic board design, design errors are often anticipated problems. The dimensions of the gaps between PCB components play a significantly large role in this sense. DFM checks can reduce production costs and eliminate unforeseen expenses, reducing the number of boards that cannot be used. DFM control can be offered free of charge with the PCB board project order as standard.