Technical Specifications for SMD and THT Assembly Processes

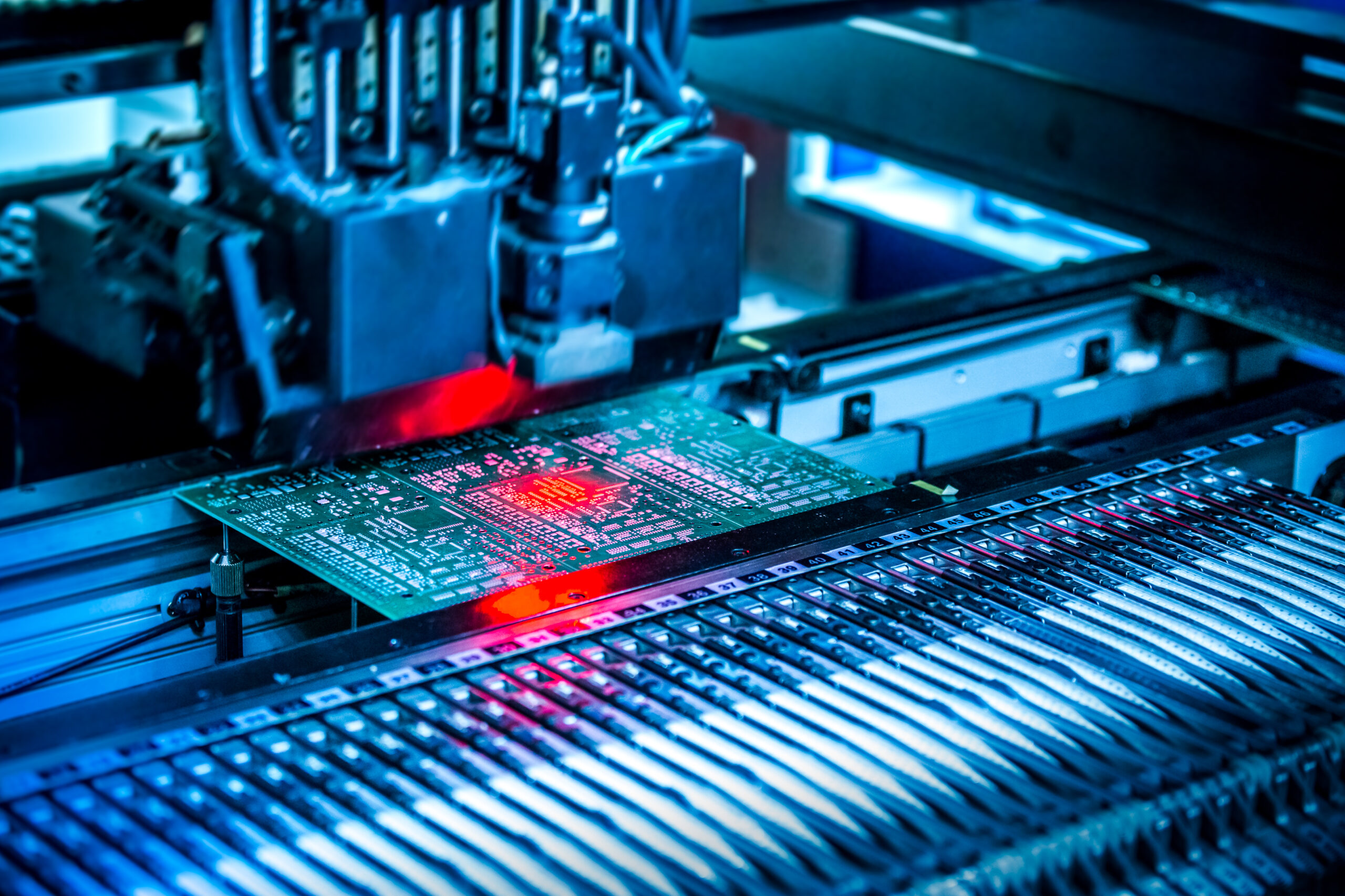

In line with the technical specifications of our SMD & THT Typesetting line, SMD and TH typesetting of all kinds of electronic cards are made in accordance with IPC-A-610 and ISO 9001 standards. Our SMD & THT typesetting line starts from our manual screen printing machine. Thanks to this machine, solder cream is applied on the PCB. Using a specially designed Stencil (Stencil) for each printed circuit board, the appropriate amount of solder cream is applied to the PCB, then it is checked and transferred to the typesetting process.

With the infrastructure we have and our staff experienced in production techniques, your cards can be designed and produced smoothly and at high quality standards without any quantity limit.

We have two separate professional lines in SMT typesetting consisting of automatic machines. Our Juki fast smart modular machine with class-leading speed up to 29,000 CPH and the other line with 50 feeders and 4 nozzles typeset at a speed of 10,000 CPH according to IPC standards.

Fully Automatic SMD & THT Assembly and Soldering

Our fully automated SMD & THT Assembly Line is compatible with a wide range of components up to 201, 402, 603, 805, 1206, 1210 and TQFP240. 4 high-resolution cameras ensure assembly accuracy down to 0.01 mm. After the assembly and soldering process, the Omron RNS II AOI is rigorously checked for problems such as cold solder, discoloration, oxidation and cracks.

Furnace and Heat Treatment: Precise Temperature Control

After SMD & THT assembly, the PCBs are transferred to the oven by conveyor. The furnace operates in the range of 25-300°C, offering ±1°C accuracy and ±2°C PCB temperature deviation. With a total of 12 heating zones, top 6 + bottom 6, the required profile is applied exactly and the solder quality is optimized.

Contact Us

You can contact us at any time for your questions, requests or cooperation opportunities.

Our team will get back to you as soon as possible.